Phone

Call us during our official business hours. Outside official business hours, you can reach us via E-Mail.

Available by phone: Monday – Friday 09:00 – 12:00, 13:00 – 18:00.

Call us during our official business hours. Outside official business hours, you can reach us via E-Mail.

Available by phone: Monday – Friday 09:00 – 12:00, 13:00 – 18:00.

In any case of emergencies outside the official opening hours, you can reach our on-call Service. Please note the additional costs for special operations.

Thanks to Videoconferencing, you can give us access to your device. This way, we take care of the predicaments you're in or concerns you have via remote maintenance, which saves time and resources.

For more minor time-critical requests, use the contact form on our website https://Scaleoperate.com/ or E-Mail us a message with your questions, on info@Scaleoperate.com.

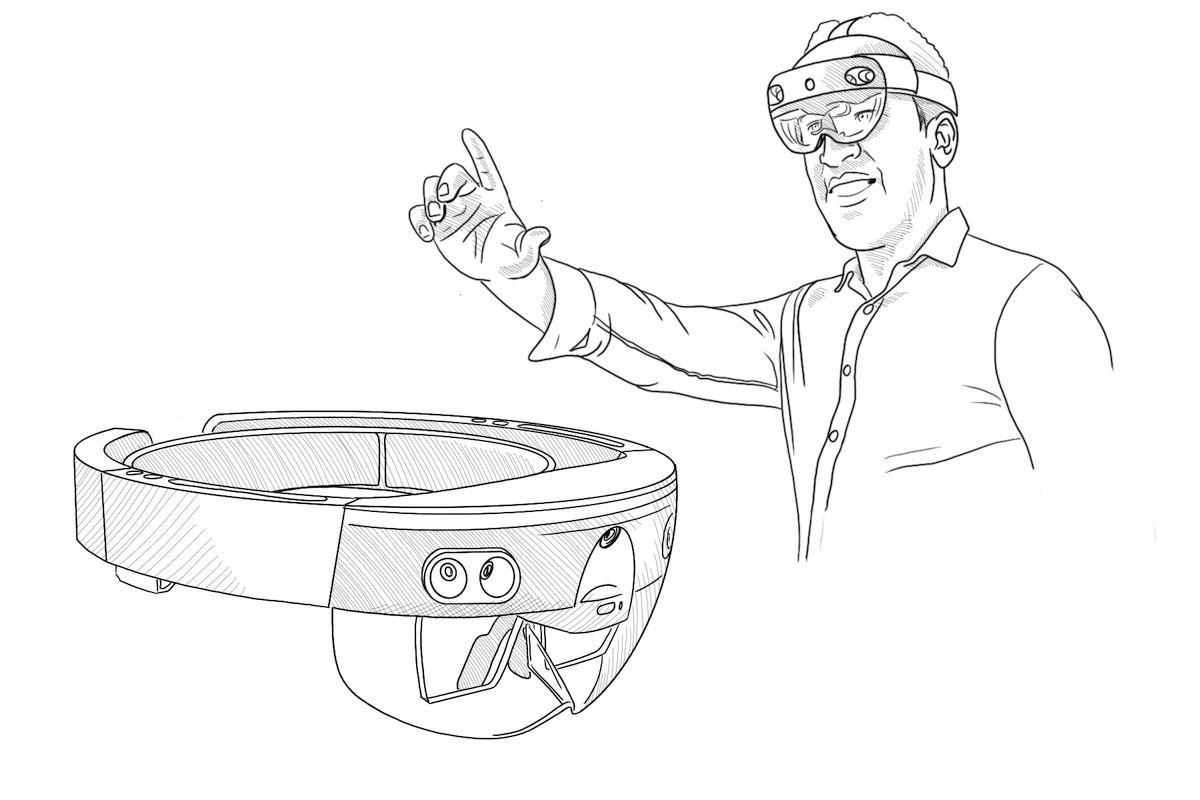

As there are fewer experienced professionals in the field of Engineering and CNC machining, Augmented Reality technology is trying to bridge the knowledge gap between newcomers and the older, more skilled generation. As it becomes increasingly difficult to pool and conglomerate knowledge, to hand over to a younger generation. AR technology makes it possible to simulate a workflow step by step, using the accumulated knowledge of senior CNC operators. This enables newcomers to apply the concept of learning by doing and muscle memory.

This interactive learning method also allows remote troubleshooting without the need to incur travel, expense, and logistics. Implicating that each expert is available remotely around the clock, 24 hours a day, 7 days a week, worldwide.

Augmented Reality (AR) technology has found diverse and innovative applications in Industry 4.0, which are primarily aimed at supporting production workers and technicians in their work environment. AR glasses equipped with this technology can provide guided assistance to production workers or technicians through a remote assistance system supported by remote experts. This technology enables real-time visualization of tasks through displays on mobile phones or AR glasses. Additionally, AR-enabled scanners can scan and capture objects, creating digital twins of objects or virtual representations of real-world objects that can be analyzed, predicted, and optimized for productive activities.

AR technology is particularly advantageous because it allows the simulation of a process' operating parameters and the assessment of different scenarios without disturbing the real environment. This capability improves decision-making, improves reliability, and maximizes productivity. In addition, AR technology allows users to visualize step-by-step procedures of a task and receive real-time instructions from remote experts, making it a crucial tool in areas such as maintenance, assembly processes, and quality control across numerous industries.

Maintenance solutions using AR technology are purposefully designed to improve the performance of on-site technicians and eliminate inefficiencies caused by insufficient operational knowledge. In summary, AR technology has revolutionized the production environment by providing workers with valuable insights and guidance, resulting in greater productivity, efficiency, and accuracy in operations.

Scaleoperate is a forward-thinking and progressive CNC contract manufacturer committed to delivering unparalleled customer support and helpdesk services while maintaining a competitive edge. To achieve this objective, Scaleoperate recognizes the importance of integrating Artificial Intelligence (AI) technology into its ODOO ERP system, as well as AR technology with AI software embedded in Microsoft HoloLens AR glasses, which are used for real-time product assessment. This integration provides clients with a plethora of benefits that ultimately result in superior information exchange and communication. One of the most notable advantages of AI- integrated ERP systems is the capacity to gain profound insights into data. With the production of vast quantities of data on a daily basis, manual analysis and pattern identification can be tedious.

However, AI algorithms facilitate rapid and precise data analysis, uncovering correlations that would otherwise elude human detection. This enables Scaleoperate to make informed decisions about production processes, materials, and more, ultimately leading to the fabrication of high- quality products and more efficient production cycles. Another prime advantage of AI-integrated ERP systems is the automation of numerous routine processes, which liberates valuable time for engineers and other highly qualified workforce. This results in increased productivity and more effective resource allocation, leading to expedited delivery times for customers. Additionally, AI-integrated ERP systems improve the client's experience by analyzing customer preferences, feedback, and complaints, enabling Scaleoperate to make informed decisions about product design, marketing, and more.

This results in products that are tailored to customer needs, leading to a more satisfied clientele.

Enhanced inventory management and demand forecasting is yet another notable merit of AI- integrated ERP systems. By analyzing data on historical sales, current inventory levels, and market trends, Scaleoperate can more accurately predict demand and adjust production accordingly. This results in a more efficient utilization of resources, reduced out-of-stock, and ultimately, a better customer experience as clients receives their parts on time. This leads to shorter lead times for customers and an overall improved experience.

We are delighted to be invited as your Supplier on:

Arrange an appointment with us at your site if your infrastructure is too big, the device too heavy, the way too far, or the time too short to come to us.

When possible, please send us all the briefing information and details we need to prepare a comparative quote.

For this, we need:

A portion and some of our clientele or potential customers are Producing Factories desiring to penetrate the European market from Central, North and South America, as well as the middle east, Asia and far east Asia. However, they lack an established Network and connections or affiliations with European engineering firms or supply chain specialists. Furthermore, they require a partner to inspect the products and execute quality control measures before these commodities reach the European market. In this context, we serve as a supportive resource and a launchpad for European qualifications. We provide counsel and oversee the entire process, from the preliminary blueprint to CAD Design Engineering and towards production as well as delivery to the unloading site. We collaborate with premier logistics and warehousing corporations, with whom we share a longstanding relationship and strong partnership.

Our associate, ALGOMAS & TDT, is a transport and forwarding Company specializing in domestic and international transport. The acquisition of an additional fleet of vehicles and the inauguration of new storage facilities throughout Europe underscore the professional competence of its operational methodology, as evidenced by its consistent growth and success. Our logistics and forwarding partner offers cost-effective and optimized logistics solutions with a diverse array of truck types. This extensive portfolio enables us to meet a wide range of customer-specific requirements. Owing to their comprehensive fleet of trucks, we are capable of transporting nearly any type of cargo. Our objective is to provide a comprehensive solution, allowing our customers to concentrate on their core business. Moreover, technological advancements offer revolutionary insights into routing, precise forecasting, and time management to adhere to stringent delivery schedules for the customer.

Dozen of employees with long experience in logistics operations.

Dozen of our own trucks, buses and mini trucks vans.

Poland: Łowicz close to Warsaw

Spain: Montacada next to Barcelona

WEB: Algomasql.com