Philosophy

Scaleoperate

Our approach to providing solutions for the industry 4.0

Scaleoperate is a diversified company specializing in industrial solutions.

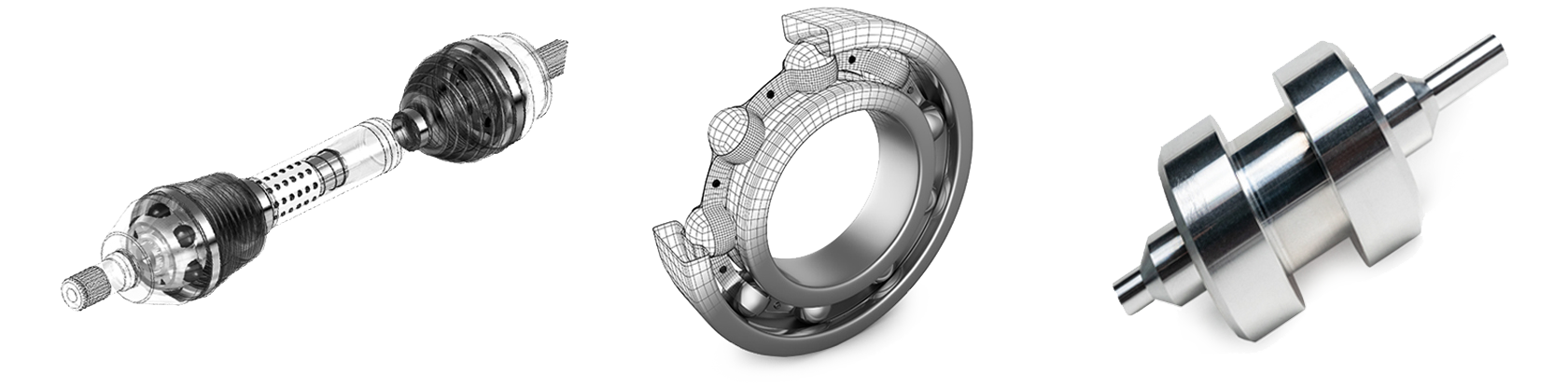

As sales engineers, we supply businesses with products in the field of machine and equipment drives for gear components and suspensions. We also support injection molding, 3D printing, CNC tooling, aluminum extrusion, quality assurance for industrial equipment, and manufacturing design.

Scaleoperate cooperates with suppliers from all over the world. We are equipped with a modern warehouse and logistic System in Europe. Our clients expect accessible communication and fast execution, which we have carefully integrated into our organizational structure and customer service. We categorically train technical consultants to help select the best solutions.

Moreover, we use reliable and proven components for our projects. Our solutions ensure optimization of production cycles with the lowest possible operational costs. We participate in the procedures of installation and commissioning at the partner's site. In addition, we deliver each product with a complete blueprint and technical documentation that complies with European directives.

- Dedicated

Team - Best

Engineers - 24/7

Support

Scaleoperate, supports & assists procurement specialists

As a Conglomerate Company we help and aid in navigating supply chain impediments as well as facilitating accurate predictions to mitigate issues.

Roughly 40% of production units persistently grapple with disruptions in supply chain management. Procuring raw materials has progressively become a daunting task, with their soaring costs and scarcities exacerbating the situation. It is estimated that 70% of factories within the industrial manufacturing sector perceive the cost of raw materials as the paramount risk to their supply chain. The deficit of raw materials has diminished, and prices have reverted to pre-COVID-19 pandemic, warfare, and economic crisis levels, considering the looming geopolitical circumstances. Nevertheless, the steel deficit endures and continues to influence various sectors. Some enterprises have deferred their expansion projects due to the spiralling cost of supplied materials. However, Original Equipment Manufacturer (OEM) fabricators must also keep an eye on other elements such as escalating interest rates, potential sales losses, and more problems that may arise. The economics of manufacturing and limited inventories have unveiled issues in engineering, production, and supply chains.

Organizations with the requisite financial resources are pondering a return to the era when they used to accumulate their inventories, leading to a surge in demand for storage space. This necessitates that all integral aspects of design engineering and construction, as well as the manufacturing process, warehousing, and logistics via road transportation must be considered to detect mistakes and defects early in the order fulfilment process. This is why the integration of automation and AI is becoming increasingly vital to support procurement professionals in their demanding ordering tasks. At SCALEOPERATE, we aid and support procurement professionals by encompassing all areas required by purchasers. We not only manage the customization of desired parts, but we also oversee design engineering as well as the manufacturing, logistics, and delivery as a unified service. All of this is coupled with real-time trackers and live webcams, which provide a behind-the-scenes insight and thus offer the opportunity to react immediately to errors and deficiencies. Our team supports all purchasers from inception to completion to tackle the challenges collectively.

Professional personnel & workforce to coach & consult

With conceptual consulting & advice, we scale your business by guiding and following you step by step through all obstacles in the production cycle.

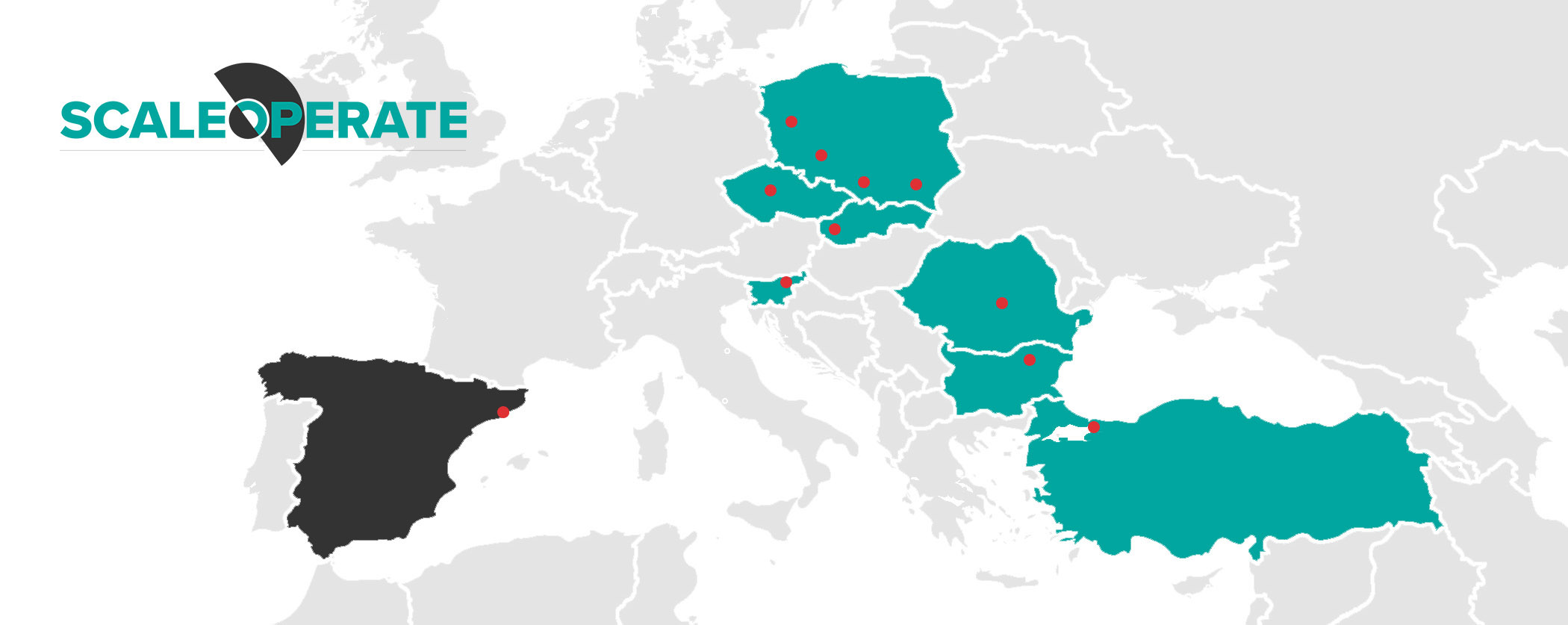

Our team, composed of experienced R&D Engineers, CAD designers, mechanics, automation technicians, machining and production line experts as well as warehousing, forwarding, and logistics specialists diligently monitors and pay careful attention towards the success of your projects. We meticulously analyse the needs of our clients and carefully strategize each task to be accomplished. This is all done with the aim of effectively and timely realizing the investments entrusted to us. We aspire to be a dependable partner, since your success is also our success, we want this collaboration to work and therefore looking forward to a long-term cooperation. Our main office is strategically located in Barcelona, Spain. From this hub, orders are delegated to the appropriate factory and production facilities. Manufacturing operations are carried out in various locations including Barcelona, Spain; Wrocław, Poland; Bucharest, Romania; Prague, Czech Republic; and Gebze/Kocaeli, Turkey. From these locations, we directly forward the finished products to you. Additionally, our extensive partner network enables us to accept all orders, irrespective of their complexity or capacity. Moreover, we can fabricate all requested parts without the necessity to find another manufacturer for specific materials.

In addition, we maintain collaborative ventures with companies from Pakistan, India, China, and Taiwan. This enables the procurement of parts that are not readily available throughout Europe or do not meet European standards and can only be sourced from Asia. Our years of expertise in these markets position us as a trusted partner for securing and expanding supply chains. We also provide coaching and consultation to buyers who work for our corporate clients or internally at an Original Equipment Manufacturer (OEM). We explore all possible scenarios to identify and circumvent potential obstacles and their sources. With us, manufacturing companies are always on the safe side, as we have a proven track record of successfully overcoming challenges. In this regard, it is in our interest to provide non-obligatory advice to our clients before placing an order, so that trust is established, and we can build on a solid foundation. After all, we aim to operate with due respect, honesty, truthfulness, reliability, openness, and transparency.

Industry Fields where Scaleoperate is active and operates

- Aerospace and Defense

- Apparatus and mechanical engineering

- Automation and Control technology

- Automotive, Aviation, and Shipyard industry

- Brakes and multi-disc brakes

- Drives and DC Tubular motors

- Electronics, Optoelectronics, Semiconductors and Switchgears

- Energy and Resources

- Food Processing

- Gaskets and Seals

- Gates, Sluices, and Latches

- Hydraulics and pneumatics

- Measurement Technology such as Optics, Sensors, and Laser devices

- Medical technology

- Pumps and Valves

- Railroad industry

- Robotics

- Transport and Aviation

- Watchmaking

- Windows and Awnings Manufacturing

Our Office

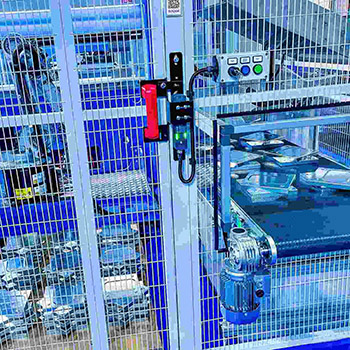

At our headquarters, the Central Office located in Barcelona, Spain; we receive and evaluate customer inquiries (RFQ's) through our state-of-the-art automated, cloud-based AI system. These orders are then allocated to one of our factories distributed throughout Europe, including but not limited to Spain, Poland, Romania, Czech Republic, Slovakia, Turkey, Bulgaria, and Slovenia, where they are processed based on construction drawings and CAD drafts. We hold transparent, reliable, and honest communication in high regard, and continually strive to develop comprehensive solutions, by adapting to novel technologies and refining our processes. Our commitment to optimization is exemplified by our willingness to openly share requests and offer examples in order to enhance potential collaborations and create added value for our clients.

By partnering with us, we can support your procurement process and service a broad range of orders. Working with us provides the distinct advantage of having a regional contact person proficient in the languages of the DACH-Scandinavia-BENELUX regions, following LEAD qualification. Our contacts are fluent in English, French, Spanish, German, Polish, Czech, Ukrainian, and Russian, among other languages.

We recommend distributing orders among various providers and suppliers based on their competencies. This process can be seamlessly integrated into our ERP system, granting access to not only us but also other suppliers, thus allowing us to immediately pass on infeasible cases. Please be aware that orders may need to be placed manually for the first time, as automation is not yet fully implemented without API Synchronization. However, our system will ultimately automate the mediation process, freeing you from unnecessary administrative work.

As a buyer, you may have had prior experience with platforms such as Haizol, Xometry, Orderfox, Facturee, Techpilot, etc… Regrettably, in many instances, neither the customer nor the manufacturers are content with the price, trust, or quality. In our industry, personal communication still holds great importance, and AI and other technologies only serve as supporting functions to transform the manufacturing industry.

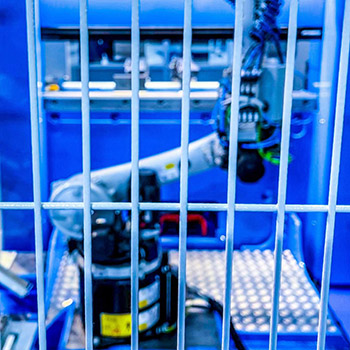

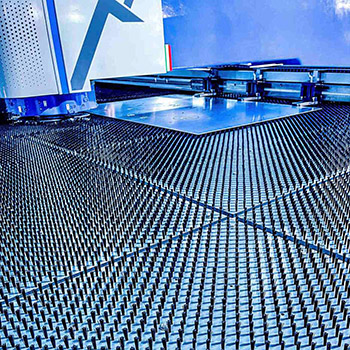

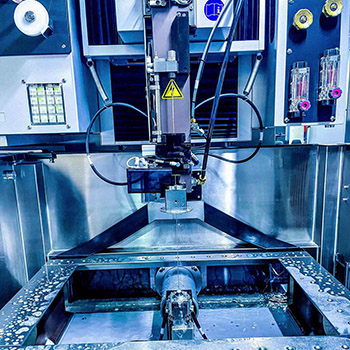

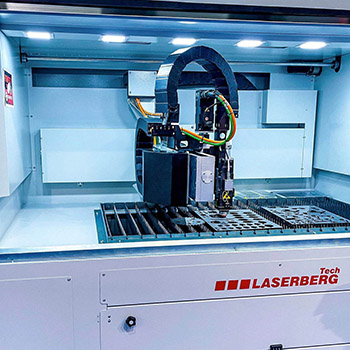

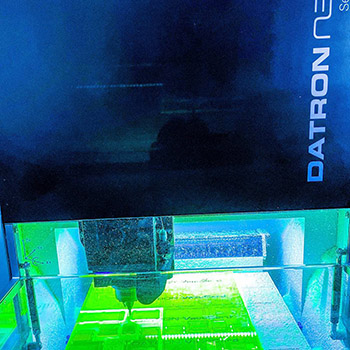

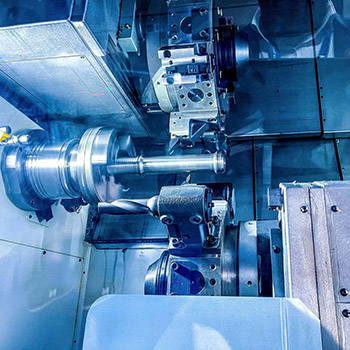

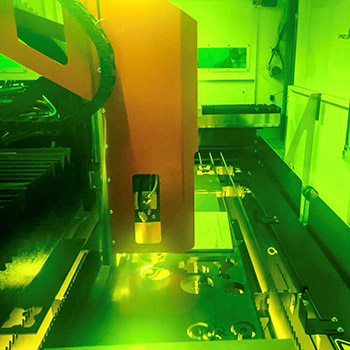

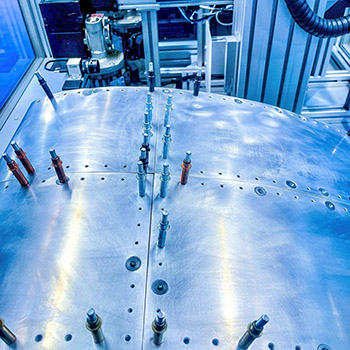

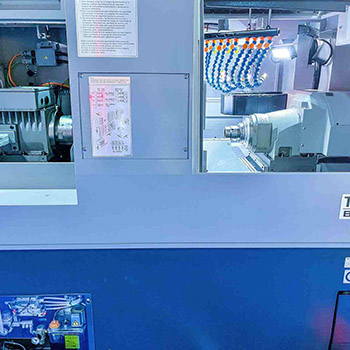

Our Factory and Machinery

Scaleoperate provides a wide range of services, including the production and supply of semi-finished products and assemblies through contract manufacturing. Our expertise lies in the production of high-precision metal, plastic, and carbon products, with production facilities located throughout Europe, including countries such as Spain, Poland, Romania, Czech Republic, Slovakia, Turkey, Bulgaria, and Slovenia. We obtain our semiconductors from top manufacturers located in Taiwan, South Korea, Japan, the United States, China and India.

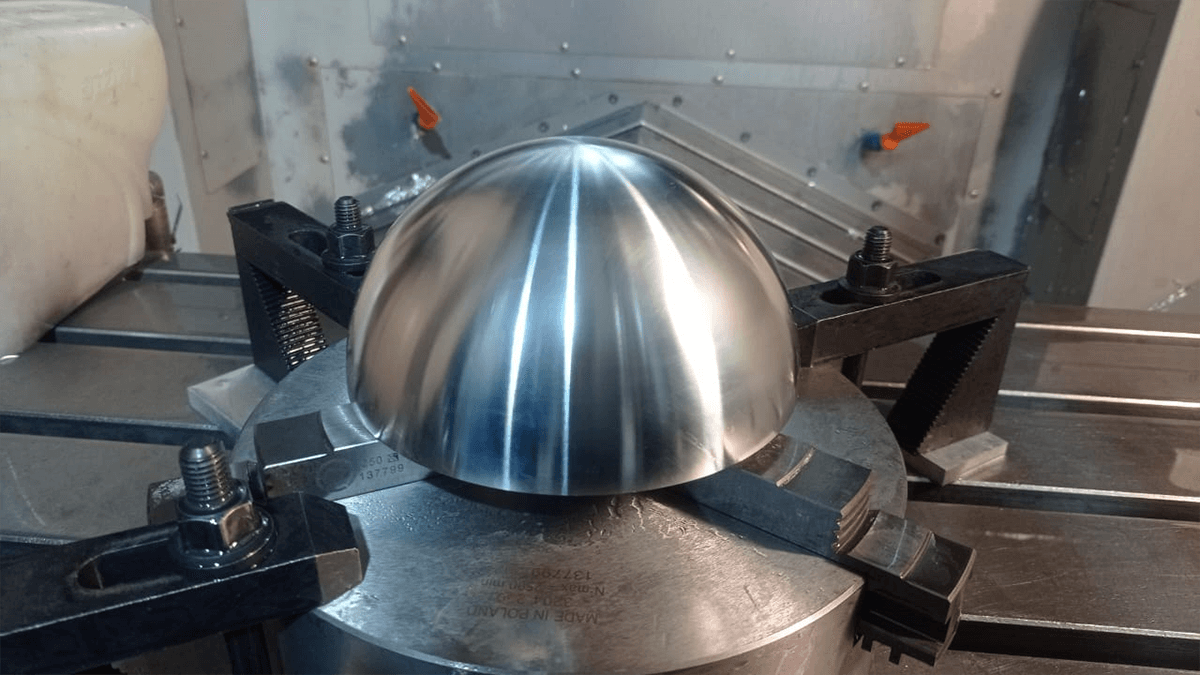

Our customers depend on our precision engineering skills to deliver contract manufacturing services on an international scale. Our capabilities encompass a variety of engineering processes such as CNC milling, turning, grinding, welding, drilling, cutting, pre-assembly and assembly. Additionally, we offer casting machining, welding services, equipment repairs and retrofits as well as intricate machining of gauges, probes and mechanical components. We can handle large quantities as well as smaller series production. Our expertise includes prototype construction and quality assurance. Our state-of-the-art machinery ensures that our customers receive top-quality products with short delivery times.

Following a consultation, we offer a comprehensive range of services that include both subtractive and additive manufacturing techniques.

Subtractive manufacturing, which includes processes such as aluminum extrusion and CNC metalworking, involves removing material from a workpiece to achieve the desired shape. This is a traditional method that is widely used in the manufacturing sector. On the other hand, we also specialize in the production of parts through additive manufacturing. For plastic/polymer prototypes in particular, the 3D printing process is used, where material is systematically added and joined to produce parts from 3D model data layer by layer, as opposed to subtractive manufacturing methods. In this process, the material is heated and extruded layer by layer through a nozzle and then cooled to form the desired object. This method can be used to produce complex shapes and structures that would be difficult or impossible to realize using conventional manufacturing methods.

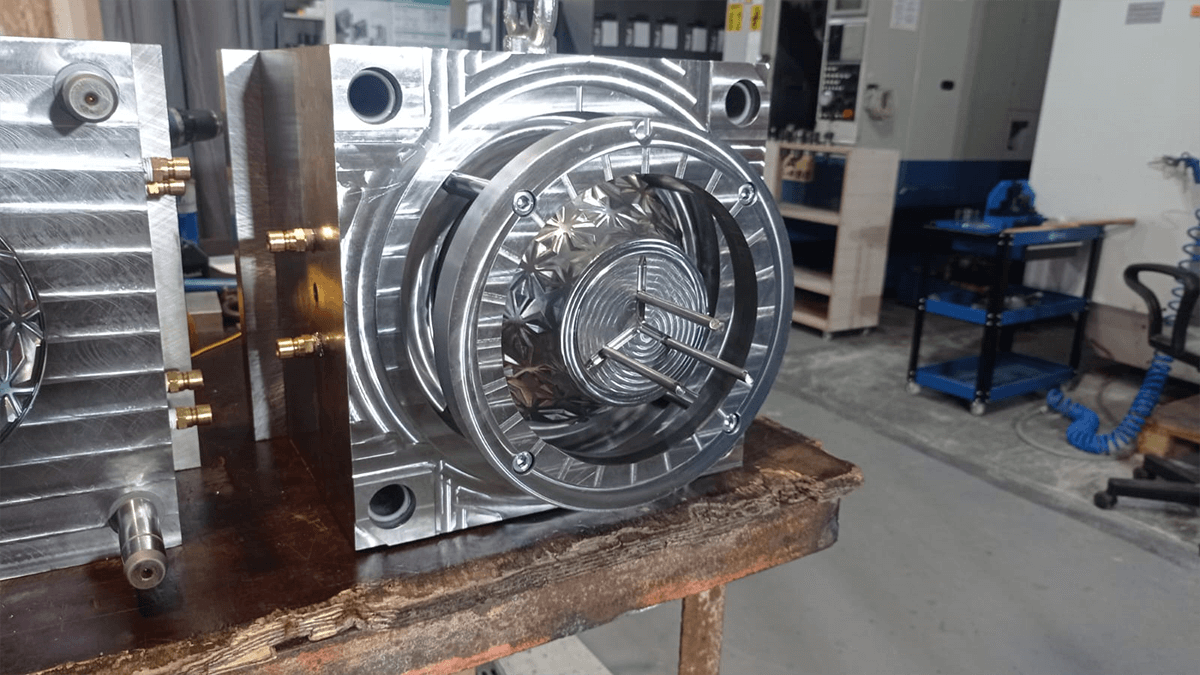

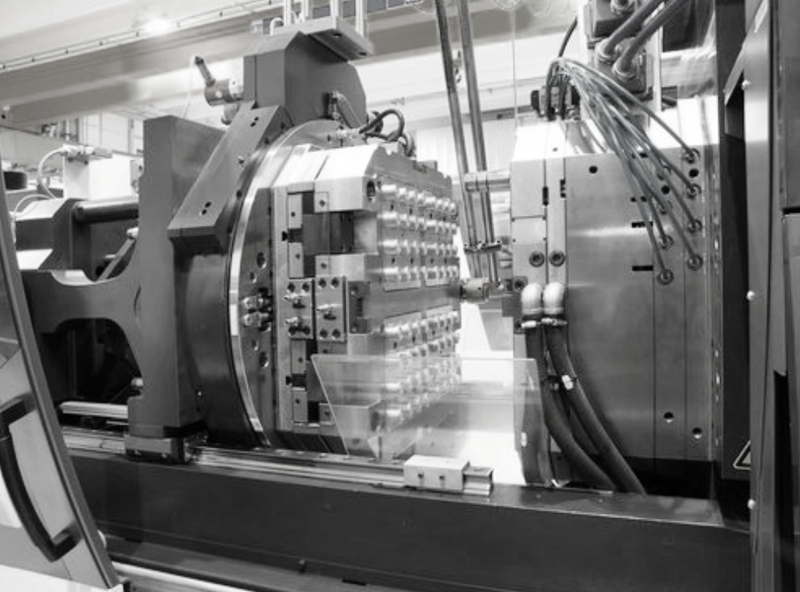

To produce larger quantities of plastic parts, we also use additive manufacturing as an alternative to subtractive processes. This requires the use of a mold, which is then filled using the injection molding process. In this process, we produce the molds in the tool shop, where later the polymer material is pressed into the intended shape under the pressure of the injection molding machines. In summary, our services cover a wide range of industrial manufacturing needs, from mechanics and procurement to supply chain management and production engineering, offering both traditional and innovative manufacturing solutions. Our commitment to the use of both subtractive and additive manufacturing techniques ensures that we can meet diverse and complex production requirements.

Dedicated plants for further cooperation

B8 Group

Team

40 employees: Designers, engineers, welders, locksmiths, CNC operators.

Machine park on 3000m2 production plant

Plasma burning - table dimensions 2000x6000 mm ; Saw cutting up to HEB 350 ; Guillotine cutting - table width 3000mm to a thickness of 10 mm

CNC press brake bending - width up to 4000mm at 600 tons pressure.; Welding - 21 Mag welders, 5 TIG welders ; Wet painting - painting booth 4000 x 6000

Overhead crane 16 tons, height to hook 12 metres ;Turning; (up to Ø750 diameter -CNC and conventional)

Milling; (table size: 500 x 1000 mm - CNC and conventional) ; Round grinding; (fi 400 x 1000 mm maximum)

Surface grinding; (table dimension 200 x 500 mm) ; Hole grinding; (fi 300 x 400 mm maximum)

Certificates

ISO 9001, 14001, 45001. Railway:50155, Welding: 3834, Strucutres welding and assembly: 1090

Average turnover

7.000.000 EUR

MetalERG

Team

150 employees: Designers, engineers, welders, locksmiths, CNC operators, quality control.

Machine park and services

Turn machines

1-spindle diameter of the machine. matt. 3÷63mm

5-spindle AN Average machining process 26mm

6-spindle DAM 25, Gildemeister AS 48

Tractor turning mills, turret lathes

Universal milling machines, vertical milling machines, tool milling

machines, CNC milling machines

Presses from 2,5 to 200 tonnes

Guillotines up to 8 mm

Edge presses:

120 tonnes, 4,0 m CNC

160 tonnes, 3,0 m CNC

600 tonnes, 6.0 m CNC 6,0 m

Cylindrical drilling machines, radial drillers, table drills, precision high speed drilling machines from Ø 0.15 mm

Sanding machines for planes,holes, shafts and tools

Horizontal CNC machining centre

Horizontal double pallet DOOSAN CNC machining centre 850x850x1000

CNC DOOSAN DBC110S boring machine CNC DOOSAN DBC110S

CNC Vertical machining centre x2

CNC CNC lathe DMG DMG

CNC CNC Lathes Storebro x3

FANUC ArcMate 1020iC 12L welding robot on a 11 m track, rotary axis and vertical and horizontal axis.

MIG MAG welding semi-automatic machines, TIG

Manual plasma cutters

SALVAGNINI L3 1500 x 3000 mm, 3 kW (fireable non-ferrous metal sheets)

CNC Pullmatic 6C punch

CNC Trumpf TRUPunch 1000

CNC plasma burner – burner 1500 x 6000 mm, x 2 (including 3D burner head)

CNC band saws

Bending machine for pipes and profiles BENDMAK PRO100

Semi-automatic spindle bender GMACC GM-SB-63NCBA GMACC

Injection moulding machines for plastics

Measuring arm

Production halls equipped with cranes from 1 to 20 tonnes

Modern spray chamber 10 m x 5 m x 4.30 m,

Shot blasting chamber

Forklifts from 1 to 5 tonnes

Zertifikate

ISO 9001, ISO 13385 (QM for medical equipment)

Durchschnittlicher Umsatz

23.000.000 EUR

Wietpol Aerospace

Team

100 employees: Designers, engineers, welders, locksmiths, CNC operators, quality control.

Machine park and services

Manual deburring and products marking (electrochemical and percussive methods) of civil and military aircraft parts

Galvanizing processes: colourless anodizing of aluminium alloys, layer thickness 5-20 µm

anodizing and aluminium dying in wide range of colours (speciality is black colour) weak-acid zinc coating with white chromate coat, layer thickness 5-20 µmColourless anodizing pots dimensions: 3000x1000x600

Colourful anodizing pots dimensions: 500x500x500

Zinc coating pots dimensions: 3200x1500x600

Painting processes (for oil&gas industry, this includes anti-corrosive resistant priming, protective coating and finishes in accordance with NORSOK Specification)

Blast cleaning processes and spray and hydrodynamic painting processes. Spray booth equipped with Wagner pumps.

3000x6000x300mm Blast cleaning chamber dimensions

4000x6000x3000mm Painting chamber dimensions

Certificates

ISO 9001, ISO 9100 for Aerospace. Company certified for delivery military products for Polish army and police.

Average turnover

8.000.000 EUR

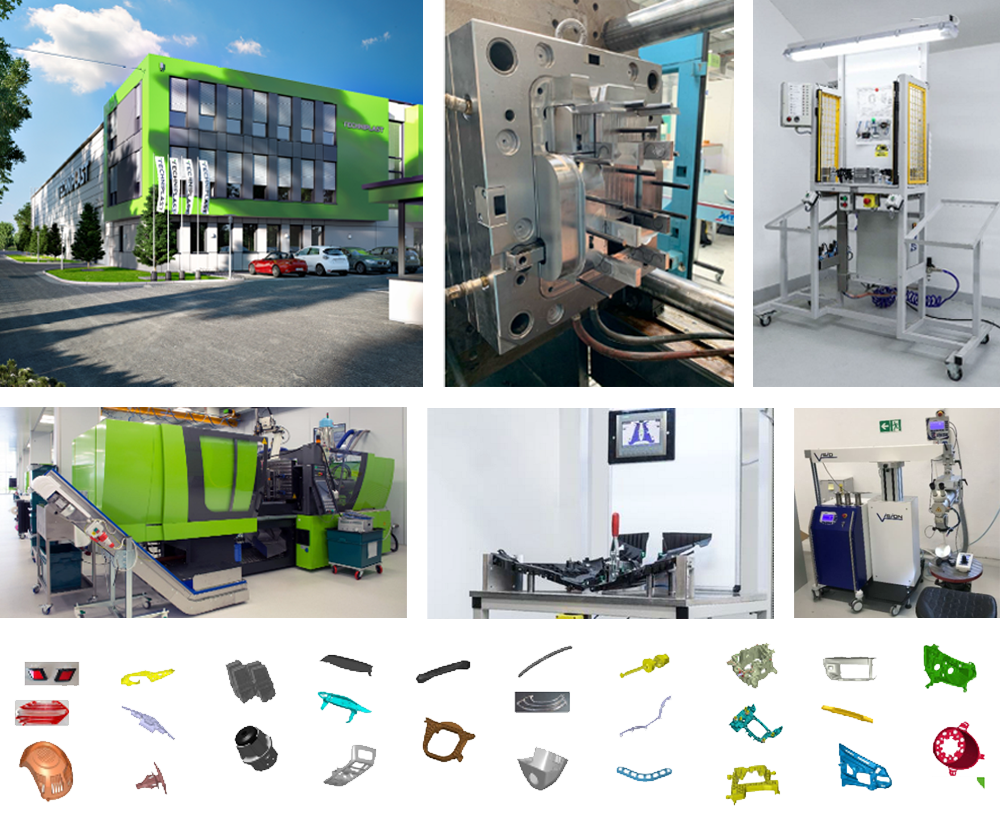

Techniplast

Team

170 employees. R&D, production, Logistics, quality, maintenance, HR and planning.

Machine park on 8700m2 production plant

25 (2 machines 2K) injection molding machines with clamping forces from 100 to 1400 tons.

Services and knowledge:

Thermoplastics moulding, Thermoplastics 2K moulding, Tassembly of plastic and metal parts.

Overmoulding of plastic and metal parts. Thermoplastics and in-line assembly.

Tool-room TECHNITOOLS company with own workshop, mainttenance and quality stations

Certificates

ISO 9001, ISO 14001, ISO TS 16949, 06/2020 Certification of IATF, Ecovadis Business Sustainability Rating.

Average turnover

28.000.000 EUR

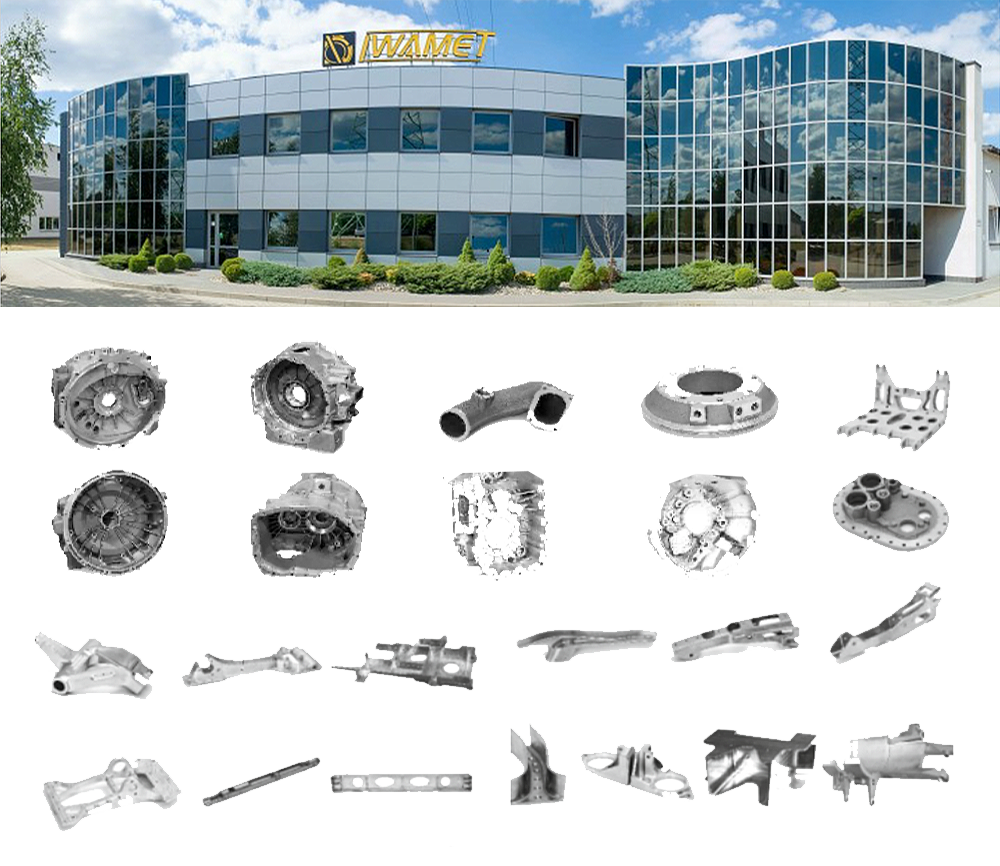

Iwamet

Team

600 employees: Designers, engineers, welders, locksmiths, CNC operators.

Machine park and services

Precision Aluminium Castings:

Low pressure die casting up to 1300mm – 60kg own tool shop

Low pressure Sand Casting

Sand Castings:

-Omega handling line – CAROUSEL, 8 station model with max 10 production cycles per shift.

-Omega Fast Loop – with max 8 production cycles with capability to produce 100 sand moulds per shift

Semiautomatic sand casting line: Max dimensions: 1000 x 800 x 650 mm ; weight 0,1 – 120kg

Hand mouldng: Max dimensions: 2200 x 1200 x 1200 mm ; weight 0,1 -320 kg ; Own pattern shop up to 5m

Precision Machning:

3-5 axis Mill/Turn CNC Centre (Makino, Hermie AG, Mikron) ; 5 axis precision machinig of large componenets up to 4m – MAG 3 ; EDM – Die sink & wire cutting

3D scanning ; ultrasonic washing machine, leakage testing (up to 30bars)

Certificates

ISO 9001, ISO 9100 for Aerospace, IATF 16949:2016, ISO 14001:2015, NADCAP Approved (FPI, XT, X-Ray), Military consessions, RINA

Average turnover

30.000.000 EUR

PRMI Promontin

Team

230 employees: Designers, engineers, welders, locksmiths, CNC operators.

Machine park 4500m2 and services

Fabrication:

MIG/TIG automatic line for pipeline DN150-DN1000

Banding station capable to bend plates up to 60mm in width 3000mm (max 4000mm)

Automating Welding line 135/136/141 method arm – max outside dimenssion of circumferencial wed dia5000 and

straigh weld 5000mm

CNC: Vision Wide NF-3232

Table size 3000x 2450mm X 3200mm Y 3200mm Z 1400mm (5axis Z 1000mm), weight up to 13t, drilling up to 600mm

Two overhead cranes – 40t ,Drilling machnes, Hydrualic press

Plasma cutter, cutting torch table 3500 x 13000 mm

3D plasma cutter for piping manifold and bewel u to DN 600mm

Certificates

ISO 9001, ISO EHS 45001

Average turnover

35.000.000 EUR

Team

Proficient, dedicated specialists with technical expertise and Company with a proven track record of production capacity to complete client projects appropriately, including experience in risk management within stipulated timelines.

Goals

- Streamlined Workflow production

- Process Optimization

- Diverse supplier portfolio

Costs

- Fixed Costs: To be aligned

- Variable Costs: To be defined

Timeframe

Initial prototypes / samples within a span of 2–4 weeks, inclusive of transportation and unloading, to specified location

Strategy

- Manufactured products

- CAD & Engineering

- Other services

Budget

- Subject to negotiation

Parts

- Raw material lead time 4 weeks

- Manufacturing 2 weeks

Production Europe or Asia

- Engineering support, testing, handovers, sampling

- Packaging, organize central warehouse and logistics services

Start-up support

- Dedicated locations in Europe

- Further consulting

Josh Hrasche & Manfred Epp

Operations & Order Processing

Adam Skalik & Krzysztof Socha

CAD, Engineering & Tools

Katarzyna Śledź

Logistics & Warehouse

Michał Kasperzec & Łukasz Biega

Quality Management & Assembly

Maciej Karaś

Produce & Sourcing

At our Machine Workshop Facility, we pride ourselves as a subcontract manufacturer equipped with a blend of both vintage and state-of-the-art machinery. It’s not uncommon for projects to be declined by manufacturers due to the potential contamination of their pristine machines. Residues from raw materials can halt operations, rendering the machine idle for an extended period. However, our experience and adaptability with various machine settings and programmability allow us to undertake projects that others might find unappealing. We collaborate with our clients, embracing risks that our competitors shy away from. Our objective is to facilitate our clients in accomplishing their targets by sharing the risk and championing their initiatives.

Even when dealing with intricate, difficult and complex components, we are willing to take on the challenge, regardless of whether it leads to immediate amortization. This approach has fostered a deep sense of respect and trust in our capabilities, establishing us as an essential ally and a cornerstone for our clients when navigating new project hurdles. At Scaleoperate, we step in as problem solvers in unexplored and undiscovered scenarios that our clients face. Our perspective is centered around assisting our clients in achieving their objectives and enhancing their reputation in front of their customers. This is why it’s crucial for us at Scaleoperate to be recognized as problem solvers in the realm of industrial manufacturing.