a complete service for

Consulting Blueprint Manufacturing Logistics

A different approach, disrupting the conventional Industry.

More about UsScaleoperate provides congruent solutions, for the many diverse requirements in the manufacturing industry.

What we do

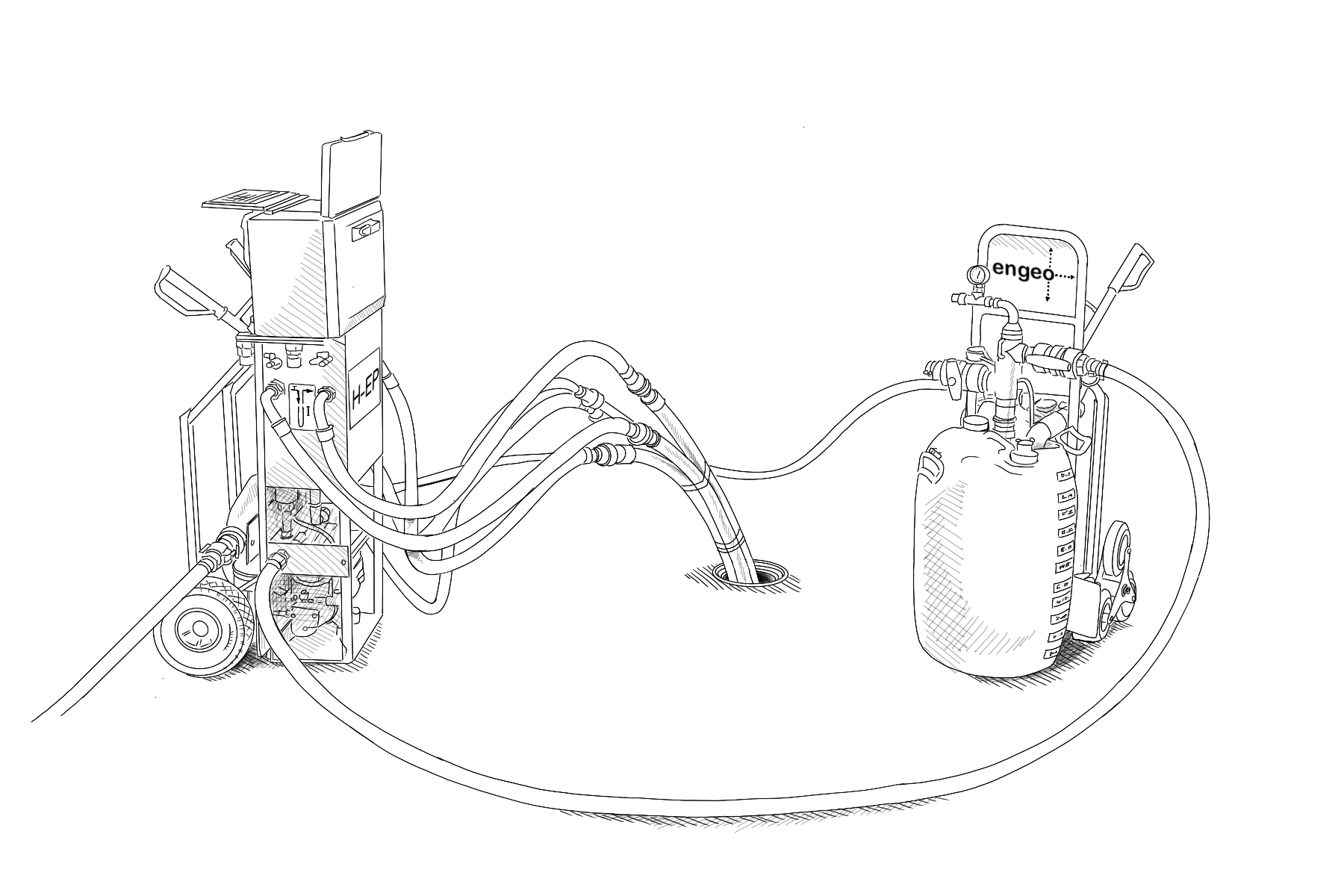

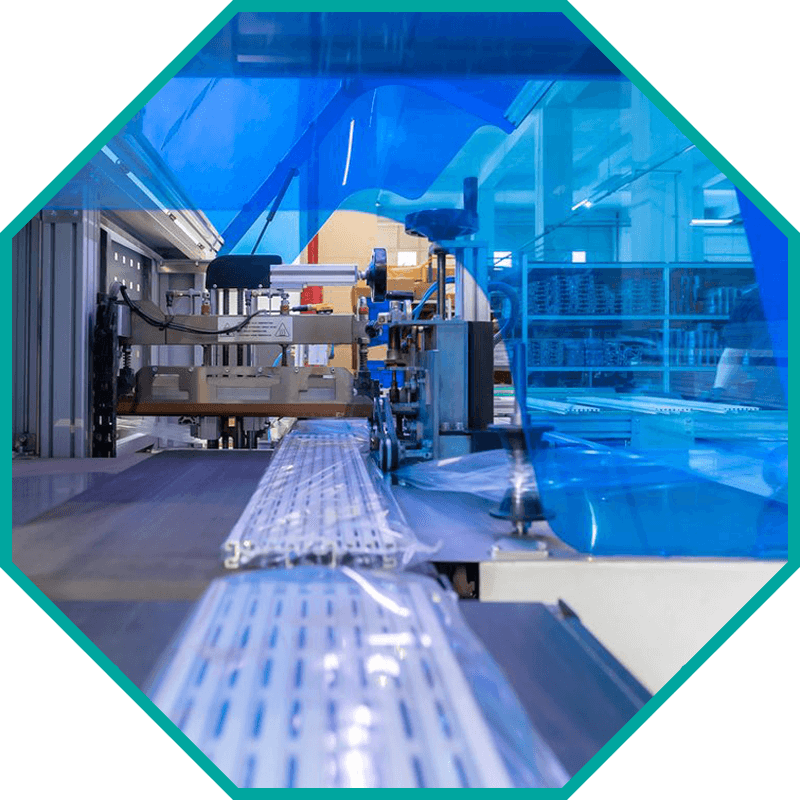

Scaleoperate is a contract manufacturer and supplier of semifinished products and sub-assemblies. We are your mechanical engineering machine workshop provider, for subtractive and additive parts production, as well as distributor of electronic components.

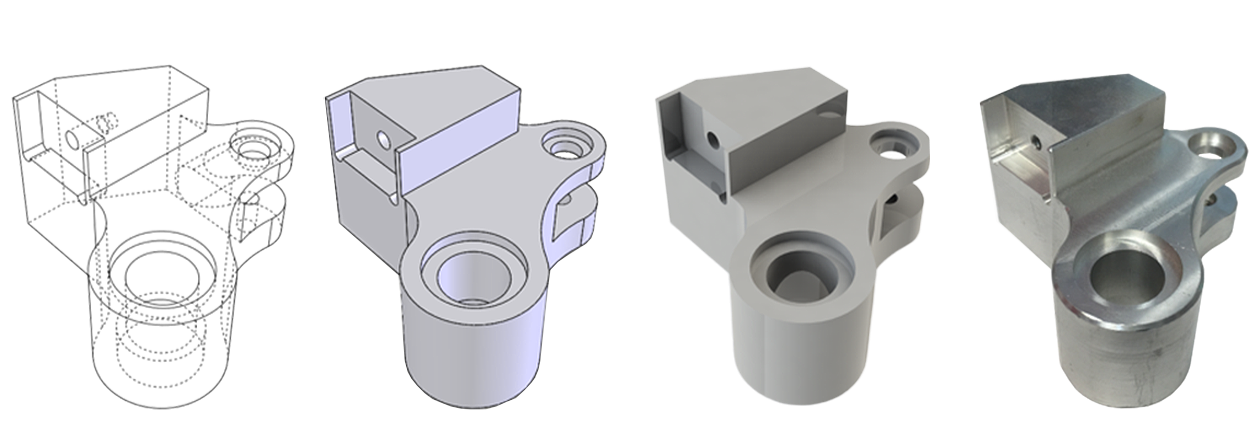

These are products that are manufactured to be consumed in another manufacturing order. Semifinished products are, therefore, the intermediate stage, from raw material to a finished product. Scaleoperate accompanies and supports its clients throughout the entire process of order fulfillment. These Operations define the activities required to complete a production order. Each of these activities, or operations, takes a specific amount of time and is performed in a particular production unit (also called a work center). These parts are assembled into a finished product. Finished products are the result of a manufacturing process.

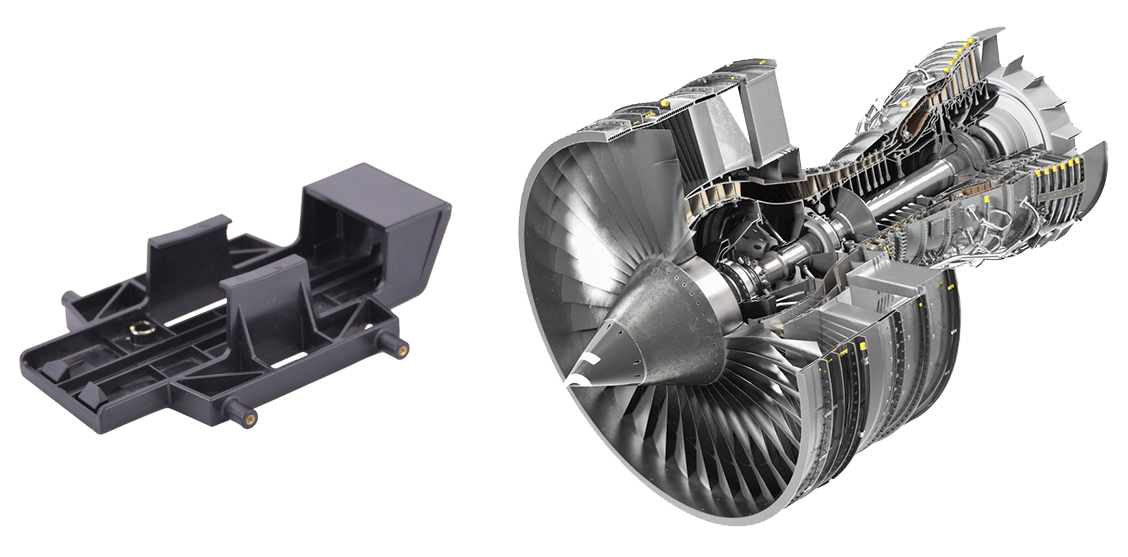

Therefore, Scaleoperate stands as a distinguished Contract Manufacturing Organization (CMO), providing subcontracting, toll, and contract manufacturing services. Thus, Scaleoperate acts as supplier of custom OEM and ODM assemblies. This positions us as an operator and contract manufacturer that not only fabricates large volume series but also caters to the production of small quantities, oversized components, and complex parts with minimal tolerances. Our versatility and adaptability set us apart in the industrial manufacturing industry.

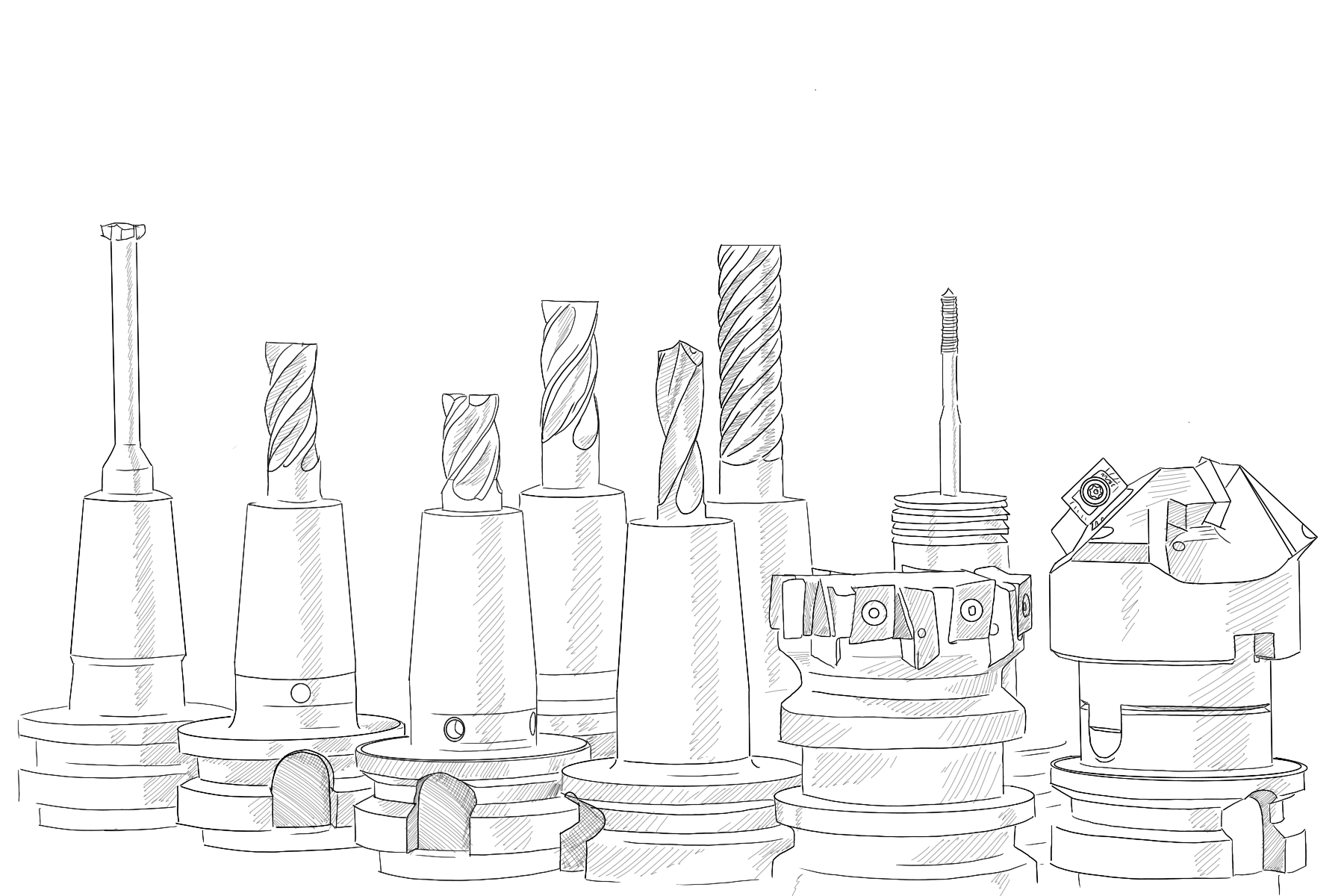

Our expertise lies in the fabrication of metal and plastic parts through the utilization of advanced machining such as CNC turning, milling, cutting, drilling, bending, welding, tapping, threading, injection molding and 3D printing to construct the desired components. Furthermore, we provide coating and anodizing services as well as the embedding, integration, and retrofitting of semiconductors and electronic components.

Our Products and Services

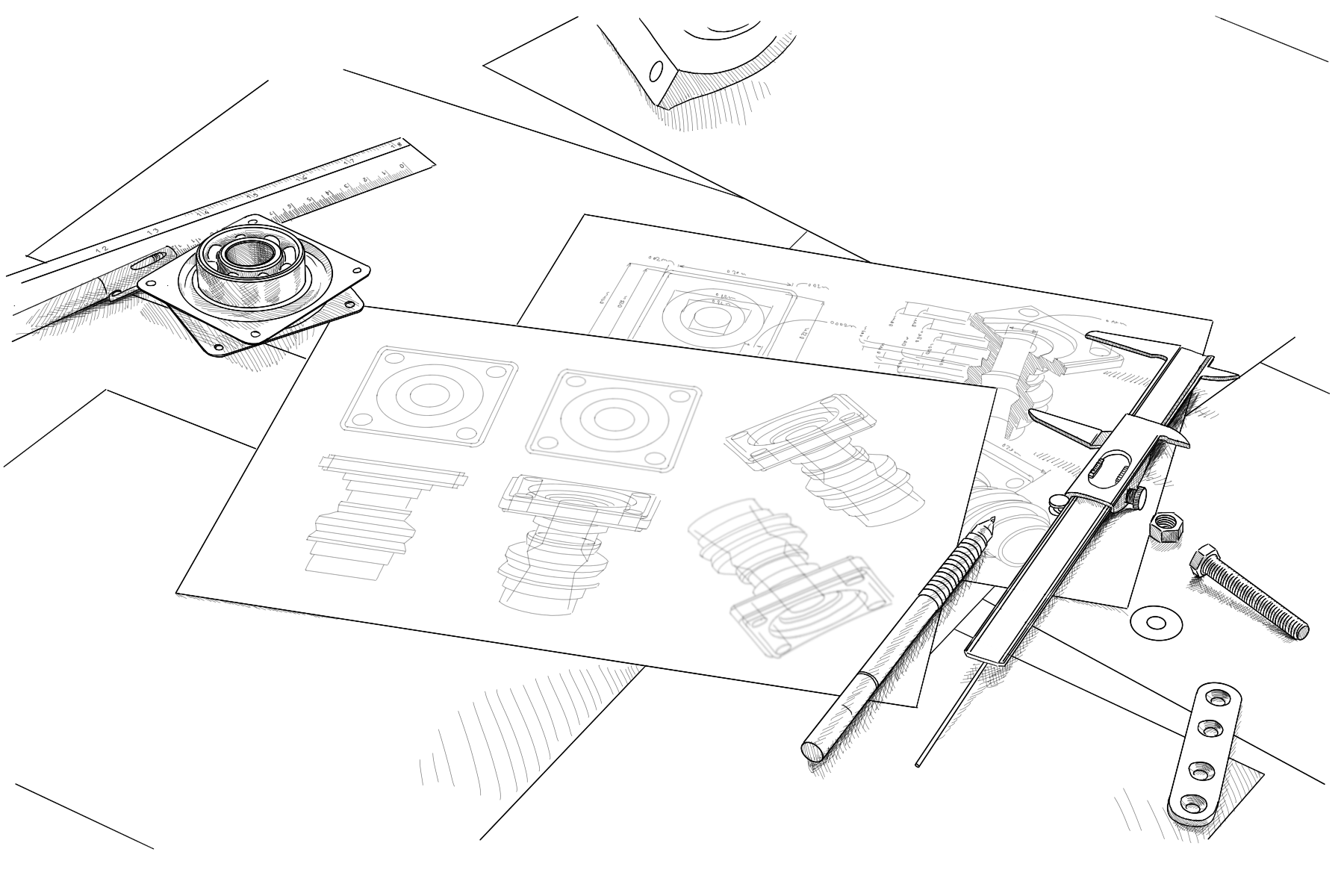

Scaling operations

Scale your operation by partnering with a supplier like Scaleoperate that manufactures difficult-to-source, hard-to-find complex parts. Our capabilities extend beyond standard offerings to encompass non-conventional products such as prototypes, limited quantities, one-offs individual units, as well as big XXL oversized components and parts that necessitate a micro minimum +/- (µ) tolerance. This makes us an alternative to offshore manufacturing, as in the Far East and China. Consequently, SCALEOPERATE is compelled to participate in more complicated, intricate, and risk-laden tender and bidding Requests for Quotations (RFQs) to secure contracts and orders within the highly competitive European market. Likewise, we also create tools for Molds, develop, produce, and distribute hardware and software for manufacturing industries and measuring instruments and semifinished products. Our Service and products are characterized by high standards of quality, meeting the expectations of our clients. As an established engineering company, we develop designs and compact constructions that demonstrate the craftsmanship of our skilled workers. We therefore ask you and your colleagues to reach out to us for inquiries, so that we can help in good timely manner.

Analyze

Production

Forwarding

Quotation / Offer

Scaleoperate's workflow procedure

Scaleoperate offers to machine semifinished products and their assemblies.

The files are examined, diagnosed, and approved by our experts.

There are cases when desired result cannot be achieved.

A project plan is provided to the customer, showing the following stages.

The tools encounter the workpiece to remove material.

Eliminating all irregularities on the part, and obtaining a flawless product.

The product is carefully packed, loaded on the truck, and shipped.

Scale your business operations

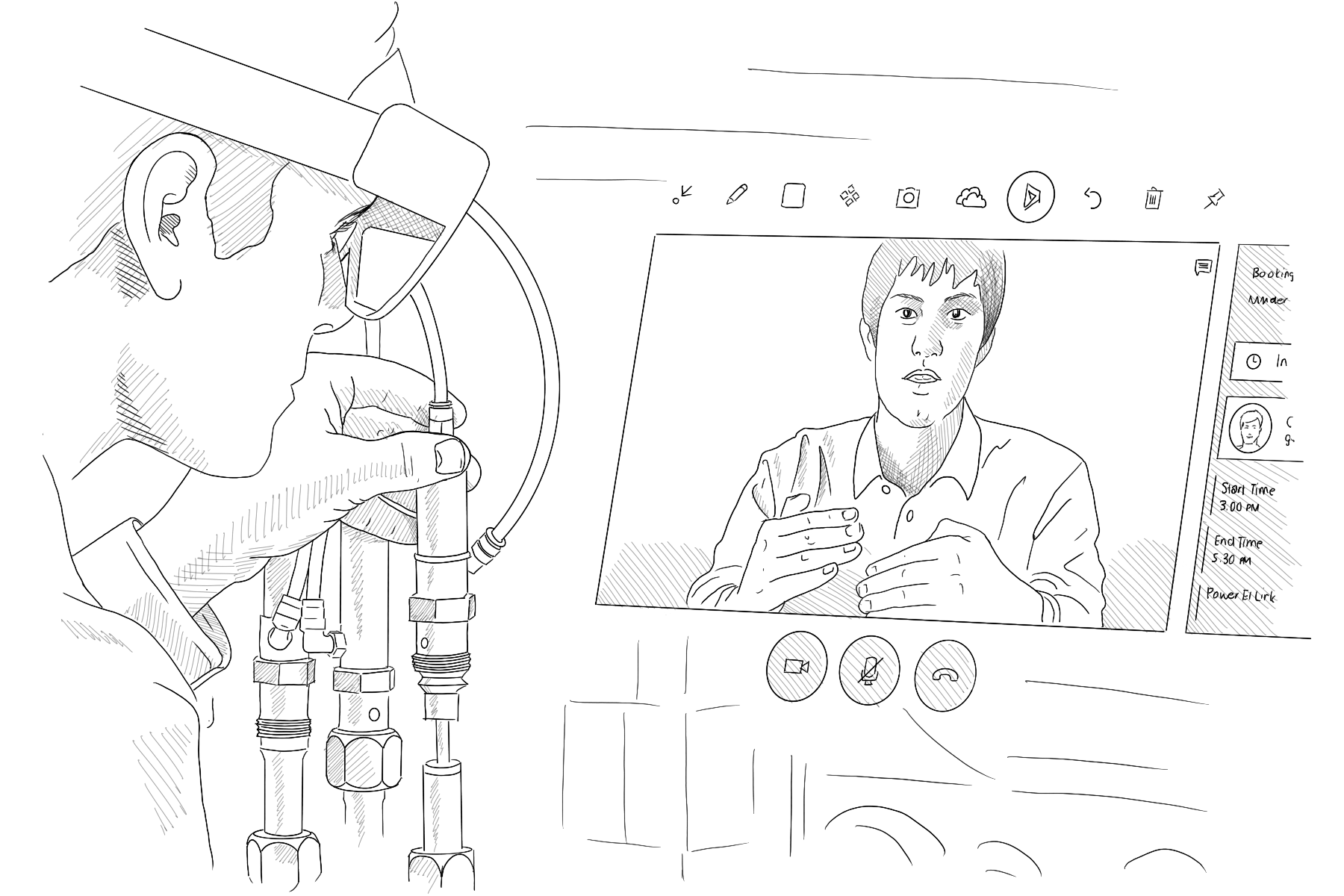

At Scaleoperate, we assume that you may have already established business relationships with reliable suppliers and achieved therefore a satisfactory level of success. We all tend to question new practices, judge, and scrutinize the approach of different concepts or strategies, and dismiss them as mere marketing sales pitches, thus perceive them as a waste of effort and time. Because we are used to common procedures that we are familiar with and don't like taking risks, on our behalf, changing established use cases might seem out of the ordinary.

It is not unusual that a former client had mentioned disinterest, and no need for us to propose and bid. Unfortunately, this myopic mindset stems from complacency and a lack of understanding. However, our team believes that optimal results can only be attained through the comparison and evaluation of multiple offerings. Scaleoperate therefore recognizes the importance of benchmarking existing solutions, and the understanding of things against our viewpoint and that of others in the market.

You already know, and are aware of, that the best results can only be attained by comparing existing offerings with others. That is why Scaleoperate is here to provide added value and help your company save time and money with less effort. Our staff of Profound Connoisseurs are well-versed in the challenges faced by procurement professionals in the manufacturing industry, when it comes to, sourcing reliable, high-quality, and cost-effective components. We invite you to evaluate our offerings, free of charge and without obligation, to determine if we can provide the ideal solution for your company. Our track record of achieving exceptional results with our clients speaks for itself.

Scaleoperate would be delighted to demonstrate our capabilities and how we can assist your company in achieving its goals. We welcome you to compare our offer in advance, on your terms. This is not a waste of time, but rather an opportunity to make an informed decision about our current position and prospects for further improvement. If Scaleoperate is unable to assist you at this time, we can still be an additional and viable point of contact for future inquiries. We achieve exceptional results with our clients and would love to show you what we have done for other companies and how we can make this possibility happen for you too.